Background information & Materials tensile structures

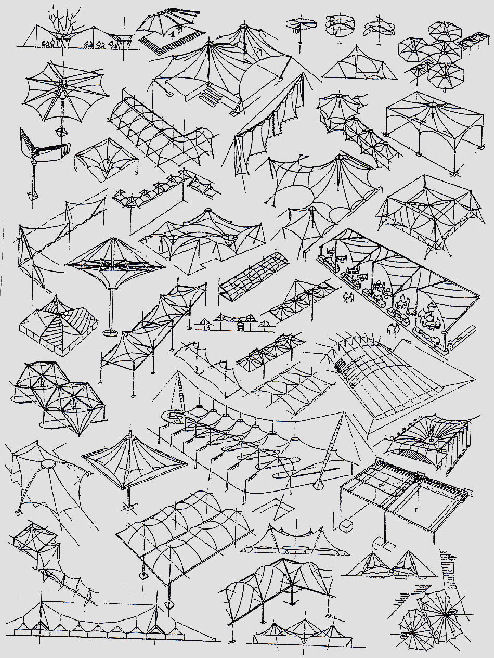

Lightweight constructions – membranes such as an tensile structure or membrane, an air cushion roof, canpoy, etc. – are from ecological point of view interesting because material properties and natural resources are used optimally. Furthermore they form an enrichment of architecture in most cases.

The main point at forming most constructions is a light (fragile) possible design. Its own weight in relation to the carrying mass should be as low as possible. Nature strengths are the enemy of lightweight constructions. Snows and wind charge (and as a result arisen ultrasounds) but also temperature oscillations, can be of large influence.

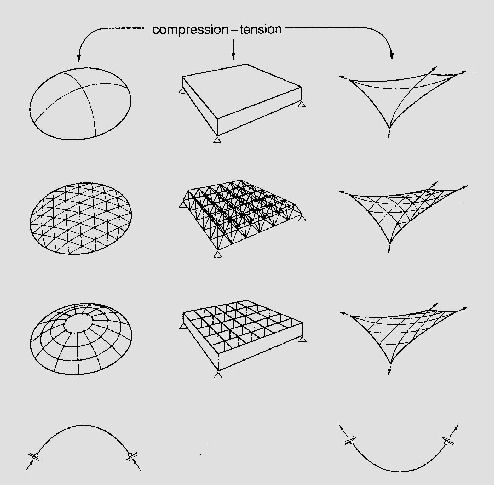

The Diagram below shows a simplified overview of compressed tensioned constructions.

Poly-Ned – Lightweight constructions, compression of tensioned constructions

source: The Design of Membrane and Lightweight Structures – Marijke Mollaert / 2002